What is the performance of an air purifier?

The performance of an air purifier depends on a number of factors, such as the initial air quality, the size of the room, its homogenization capacity and its air treatment flow rate.

Performance is also intrinsic to the device and its operating mode (filtration or adsorption system, ionization technique, photocatalytic system, etc.).

Measuring the efficiency of a purifier means carrying out a test for a specific operating condition and for a given operating time, with the percentage of the pollutant removed tracked over time.

The efficiency of an air purifier can be assessed according to the target pollutant to be eliminated. The most common air pollutants in our homes include fine particles, allergens, bacteria, viruses and chemical pollutants (VOCs, aldehydes, etc.).

TERA Environnement can help you with the “performance of a purifier in terms of chemical pollutant abatement”, and offers closed chamber testing in accordance with standards NF EN 16846-1 (B44-013) and B44-200. These standards describe the methodologies to be used when testing prototypes or commercial air purification systems for indoor air purification.

What means are available to test a purifier's performance?

Depending on the test standard and the type of purifier to be tested, various types of chambers can be used. TERA Environnement has several test benches, as shown below:

We have various chambers with volumes ranging from 1.4m3 to 30m3.

Some test benches allow air to be measured after a single pass, as in the case of ventilation systems with flow rates ranging from 50m3/h to 3000m3/h.

For systems operating in closed rooms (such as bedrooms, offices, etc.), it is possible to carry out measurements with recirculating air in hermetically sealed chambers.

Comment se déroule un test de performance d'abattement des polluants ?

Depending on the standard followed, a test may differ in terms of test duration, number of samples taken, pollutants injected and their concentrations. Nevertheless, we can highlight the various stages below.

Stages of a pollutant abatement performance test:

- The chamber is swept by a stream of fresh air before the purifiers are introduced, in order to obtain a zero state in the test chamber, known as the chamber blank.

- The system to be tested is introduced into the test bench, after which air sampling and analysis can be carried out to check that the purifier itself is harmless, i.e. does not release any chemical contaminants, before starting the pollutant abatement test.

- Various pollutants are injected through the chamber

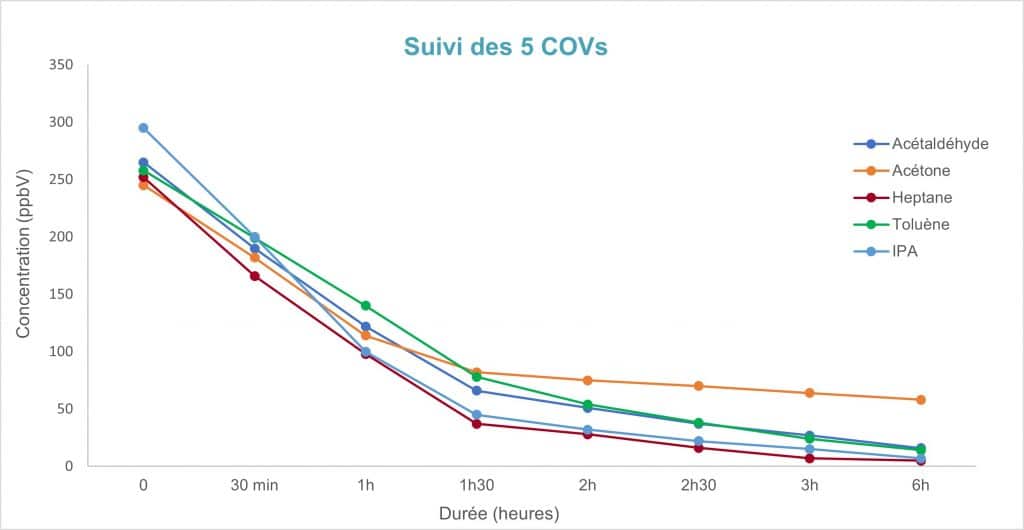

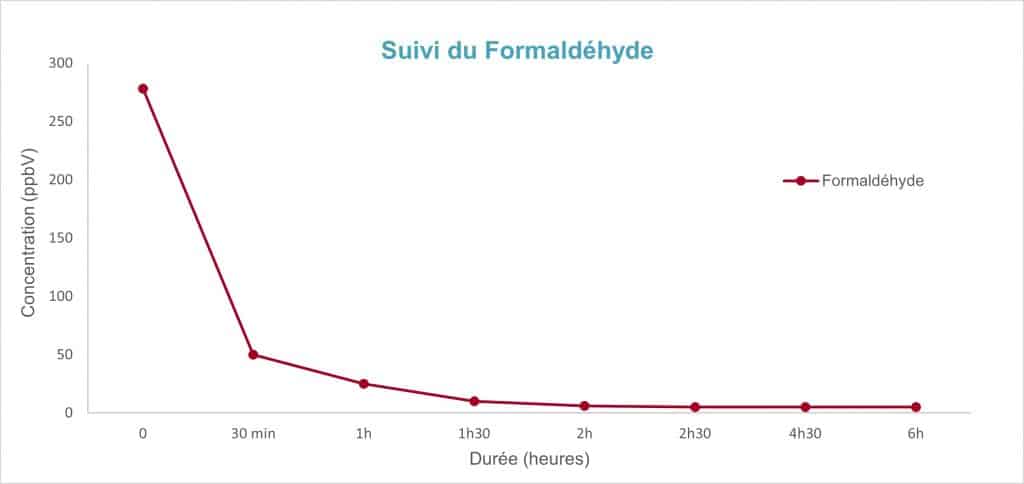

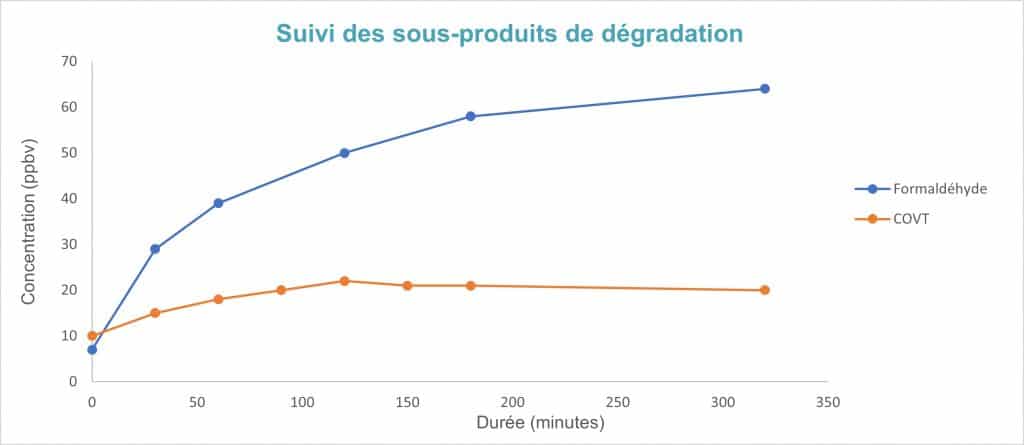

- Air samples and analyses are taken successively over time to monitor changes in the concentration of injected pollutants and the potential formation of degradation by-products.

- The results are sent to the customer in the form of a test report.

What chemical contaminants are monitored during pollutant abatement performance tests?

The pollutants injected into the chamber during abatement tests may differ depending on the reference standard followed and the customer’s requirements, but we can list the compounds below.

- Pollutants that can be injected into test benches:

2-Propanol (IPA); Acetaldehyde; Acetone; Limonene; N-Heptane; Toluene and Formaldehyde

When pollutants are eliminated by the purifier, certain degradation by-products may be formed, so it’s important to monitor their concentration over time too. The following compounds can be monitored.

- Degradation by-products that can be monitored :

Aldehydes, Ketones, Volatile Organic Compounds (VOCs) through screening, Ozone (O3), Carbon Monoxide (CO), Nitrogen Oxides (NO and NO2)

Air pollution control tests tailored to your needs

TERA Environnement has a wide range of chambers at its disposal, enabling us to offer a tailor-made solution for your air pollution control testing needs:

- Air purifier tests (refer to previous paragraphs)

- Tests on depolluting materials: please do not hesitate to contact us

Since every customer wants measurements tailored to their needs and/or priorities, TERA Environnement offers you a tailor-made service for testing your purifiers.