- Home

- Contamination control

- Surface chemical contamination

Surface chemical contamination

Why is it important to characterize surface contamination in cleanrooms?

Characterization of surface contamination in cleanrooms is essential to ensure strict hygiene conditions in these sensitive environments.

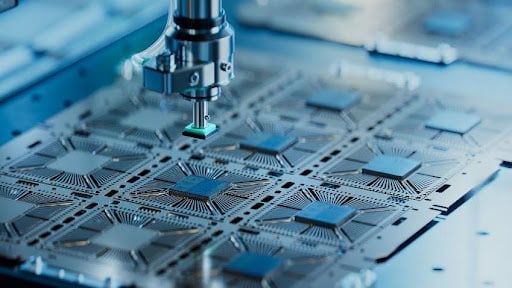

A cleanroom is a space where the concentration of particles must be kept as low as possible. This enables delicate manufacturing techniques or research studies to be carried out under sterile conditions if necessary.

International standards define rigorous rules for the operation of cleanrooms. They cover the concentration of airborne particles, air filtration, cleaning of the room, equipment, transport devices, machines and employee working clothes. These standards vary according to the sector of activity and the specific purpose of the cleanroom.

In fields such as microchip manufacturing, drug production or food preparation, surface contamination can compromise product quality. Contamination control guarantees the reliability and safety of end products.

In short, characterizing surface contamination in cleanrooms is crucial to maintaining optimum conditions of cleanliness, safety and efficiency in these specialized environments.

Why choose TERA Environnement to control contamination in your cleanroom?

Our laboratory has over 20 years’ experience in cleanroom contamination control, and is backed with high-performance analytical equipment for the analysis of a wide range of organic and inorganic chemical contaminants present in air or on surfaces at trace levels.

Find out why you should choose our laboratory to help you control contamination in your cleanroom:

- Over 20 years’ experience in cleanroom air analysis

- High-performance analytical equipment for your analyses

- Wide range of compounds that can be analyzed

- Very low analytical thresholds or limits of quantification (LOQ) ranging from ppt to ppb

- Flexibility and responsiveness

What resources are available to characterize surface contamination in cleanrooms?

- Surface sampling using a wipe

Wipe sampling is useful for assessing surface contamination, particularly in cases where no deposits are actually visible on the surface to the naked eye.

The choice of wipes to be used depends on the type of surface to be sampled, and the nature of the pollutants sought. Depending on the compounds to be tested, the wipes can be soaked in water or an organic solvent.

- Surface deposit sampling

In the case of visible surface contamination, e.g. at an exhaust outlet, where a deposit of just a few grams can be collected, the deposit can be sent directly to the laboratory for analysis.

What compounds are measured on wipes or deposits?

TERA Environnement’s high-performance analytical equipment enables us to analyze various families of compounds on wipes or deposits. Before analysis, wipes or deposits are extracted with water, acidified water or an organic solvent, depending on the compounds sought. In the case of crystalline silica, solvent extraction is replaced by combustion prior to analysis.

Compounds that can be analyzed on wipes or deposits are listed below.

- Aluminum (Al); Antimony (Sb); Silver (Ag); Arsenic (As); Barium (Ba); Beryllium (Be); Boron (B); Cadmium (Cd); Cerium (Ce); Cesium (Cs); Chromium (Cr); Cobalt (Co); Copper (Cu); Tin (Sn); Iron (Fe); Gallium (Ga); Lanthanum (La); Lithium (Li); Manganese (Mn); Mercury (Hg); Molybdenum (Mo); Nickel (Ni); Palladium (Pd); Phosphorus (P); Platinum (Pt); Lead (Pb); Rhenium (Re); Rubidium (Rb) ; Scandium (Sc); Selenium (Se); Silicon (Si); Sulfur (S); Strontium (Sr); Tellurium (Te); Thallium (Tl); Titanium (Ti); Tungsten (W); Uranium (U); Vanadium (V); Zinc (Zn); Zirconium (Zr) etc.

- Quartz; Cristobalite; Tridymite

- Acetate; Bromide (Br–); Chloride (Cl–); Fluoride (F–); Formate; Nitrate (NO3–); Nitrite (NO2–); Oxalate; Phosphate (PO43-); Propionate; Sulfate (SO42-); Ammonium (NH4+); etc.

Please contact us

TERA Environnement has been helping its customers control chemical contamination in their cleanrooms for over 20 years!